The following is a first-hand account of the (hurried) restoration of Jack Brabham’s 1966 World Championship winning Brabham BT19. The article, by Bill Freame, first appeared in the April 2020 edition of Valve Bounce, the magazine of the Gippsland Car Club.

Forty years ago, in the 1970s, I was an employee of the vast Repco organization, when it was still being run by engineers, not accountants. I was in a small department involved in product development of engine parts for the various car companies this country was blessed with at that time. Many newly developed replacement parts were also tested, before being released onto the market under the Repco name. There were several engine dynamometer test cells in use and a test rig for severe loading of Holden timing gears, plus a sound-proofed rig room for hydraulic load testing of engine bearings. All part of the development of bearing materials as Repco and Holden searched for an alternative to lead. Eventually, the old copper/lead bearings were almost universally replaced by aluminium/tin as the car makers search for more environmentally friendly materials. The research was further complicated by low friction and synthetic oils, unleaded fuels and including a great expansion in the use of LPG.

In the late 1970’s the Light Car Club of Australia, which controlled motorsport at Sandown Park, announced that Juan Manuel Fangio, five-times world driving champion, was coming to Sandown to demonstrate one of the historic Mercedes-Benz Grand Prix cars he raced in the 1950’s. This was huge news beyond the normal motor racing crowd. It seemed everyone knew Fangio. The LCCA anticipated massive crowds prepared to pay to see the great driver in action on the Sandown Park circuit.

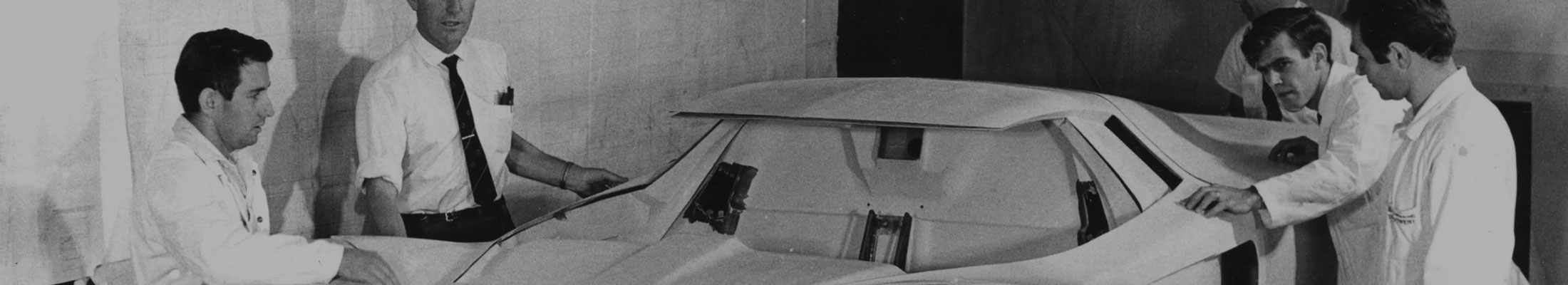

Some months before the announcement, someone within the Repco organization had (secretly) bought the 1966 World Championship winning Repco Brabham BT19, probably from Jack himself, for goodness knows how much money. With the car/ chassis being only 11- years old, it had been retired and superseded, replaced as further improvements and developments in chassis design surged with the performance of the Ford DFV that by then even the Brabham team had found necessary to use. The two valves per cylinder headed RB engines won the drivers world championship in 1966 and again in 1967, while the four valve RB engines never did that. Anyway, this purchased BT19 was in pieces, the chassis had just been repainted and it just needed to be assembled, about two or three days work

Well, Don Halpin had been sent out to the Bayswater panel shop to start assembling it, all alone, just by himself, ‘Should only take you a couple of days’, he was told. Meanwhile, there had been a broad media announcement that three-time world champion, Jack Brabham, would also be at the Fangio meeting; he demonstrating the BT19. The Fangio meeting at Sandown was only about six weeks away and everybody was expecting our triple world champion to be driving in the BT19-championship winning car. In only 6 weeks!!!!!!!! The media announcement intimated that the BT19 was ready to go, just waiting for the date to roll around.

Honestly, then, as now, I believe that it should have been the tribute to Fangio that he well deserved, without the meeting being diluted with the inclusion of our Jack. As Jack was frequently living back here, any number of tribute meetings for him could have been arranged, at all our race tracks, just about at any time, but certainly run after this Fangio meeting. Whatever were the ‘That’s a Good Idea’ thoughts at that time, Fangio should have been the only champion on show.

Don was distraught with what he discovered that he was expected to simply screw back together in a couple of days. It was not only incomplete, it was supplied with the wrong RB engine, not a ‘620’, the wrong gearbox, no bell housing or exhaust pipes. Don hastily returned to our Richmond base, to negotiate for a team for the assembly and start the manufacture of missing parts. With that agreed, all the parts were trucked from Bayswater to Richmond, to be assembled in one of the Repco machine shops with three of us added to the assembly team, making a total of only four, meanwhile most of our other projects were handballed to other staff. And so the race against a very short time frame began.

As Don Halpin had an astounding knowledge of all things Repco Brabham, at that time (and since) maintaining and rebuilding various RB engines in his own time, he was able to source most of the required pieces. For the exhaust system, Graham Facey would build the pipes, but only when the engine and gearbox were installed so he would know how much space was available. The other requirement was that the car would need to be delivered to his workshop, somewhere in the rural SE of Melbourne, for about a week. Don was able to swap enough engine pieces to have a correct RB620 engine and while that was being assembled, the ‘Magnaflux’ crack tester we had was used on many engine, gearbox and suspension parts as we had no knowledge of their history. The ‘Triumph’ front stub axles were carefully inspected and where they always crack was ground out and welded, then repainted. While the car was away for the exhaust system we continued to prepare other parts for ignition, braking system overhaul and fuel delivery. After a few days the car returned and we could then continue assembly. Unlike how the BT19 was raced, the exhaust now curved around outside the top suspension arm, out in the breeze, whereas when raced, the pipes were closer to the engine by being inside the suspension arms. A small detail but very obvious when compared to the original racing photos.

A few strings were pulled with ‘Goodyear’ and we were able to purchase newer period tyres for the car, representative of the mid-sixties racing tyres. All the electrical connections were cleaned and checked for durability, the fuel system cleaned and flushed and a battery box built to mount on the rear of the gearbox. The injection system was missing the trumpets and we had to make them as close to original as possible, a collection of racing photos helped us keep the looks of the car as original as possible. The mechanical fuel injection is pressurized by a very, very large ‘SU’ pump, mounted in the airstream, on the front of the radiator, for cooling. Post Fangio meeting, there was a cog belt driven mechanical fuel pump installed on the left front of the engine, thereafter the electric pump is now only used for starting.

As the meeting got closer, the days became longer, with early starts and late finishes the norm. The final week was frantic, with all the fiddly bits still on a long list of things to be completed. Then there were seemingly endless TV interviews, all with Jack sitting in the car. Each of the TV channels were allotted a time for an interview with him, essentially the car needed to look complete, ready to drive on the track. In between the interviews, Jack was entertained away from us, somewhere in the offices. The TV crew would arrive early to set up lighting and sound, while we would assemble the car with the body and wheels back on it. Jack and entourage would arrive, Jack would settle in the car and be interviewed, then he left while the camera was filming the interviewer asking the same questions, but to the camera, so it could all be cut and spliced for the evening news. While that TV crew retreated we dismantled the car again for more assembly and preparation. This cycle would then repeat again with another TV crew.

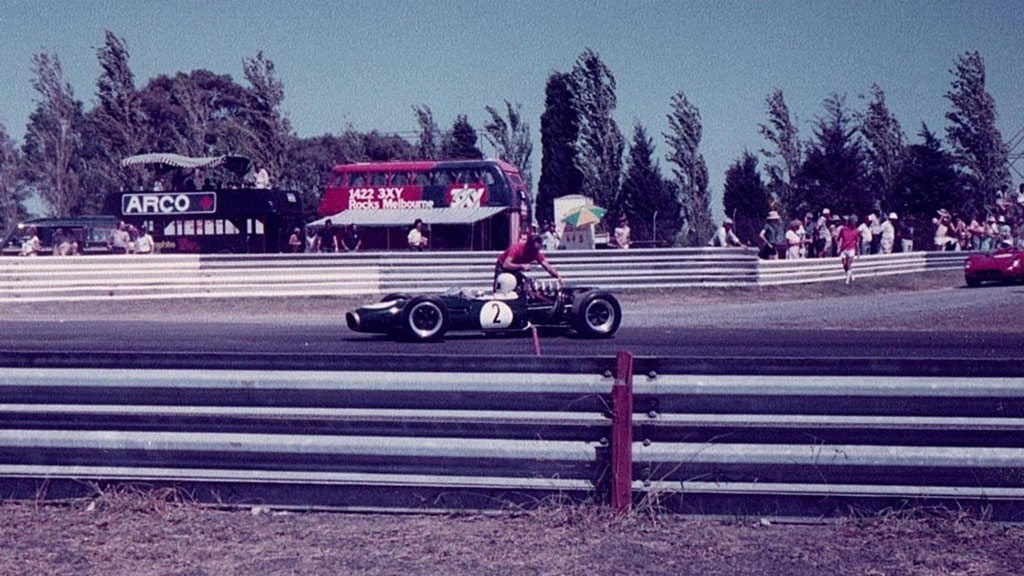

When Jack saw the almost assembled BT19 for the first time, he smiled a big smile and asked Don if it would be ready in time. Don responded that it would be ready and as safe as we could make it for him. Certainly there would be no test drive of it, its first test would be on track at Sandown, ready or not. On a borrowed trailer, eventually the BT19 was completed and sent off to Sandown, attracting almost as much attention as Fangio’s Mercedes. His Mercedes had the advantage of not having just been quickly assembled, they even had a specialist along just to blend the exotic fuel! Typically, the Mercedes Benz Company was very well prepared, nothing would go wrong to damage their company image!

The BT19 was on a diet of BP Avgas and had a slight misfire as soon as the revs got up high. Eventually a change of battery from the 12 volt we were using to a loaned 16 volt battery from Kevin Bartlett solved that, the extra voltage providing higher fuel pressure for the Lucas injection. However, the injection metering unit is actually mounted above but in the valley, and when the diaphragm suddenly sprung a leak it filled the valley to the brim with Avgas. Just how old was the diaphragm we had trusted to be OK at 12 volts but not when supplied with 16 volts?

At that meeting, all the cars were being taken off track at turn 1. Hot tyres and loose gravel! Two members of our crew were always waiting for the car there at the end of each run, just off the edge of the track, to install some mesh covers over the open trumpets, thus reducing the possibility to swallow any stones. Plus a tow rope would be attached and the car towed back to the pit area we were camped in, behind the grandstand. Don noticed the valley awash with fuel and suggested Jack vacate the car. In a single leap, Jack was out of the cockpit, his feet hitting the ground many, many feet away. Without even turning to survey the situation, he suggested we attend to that before his next run. How easily we could have BBQ’d a national treasure, and the car too. Thus, with a hot engine, valley full of fuel, we got to tow it back through a vast crowd, some of whom may have been smoking.

There were many things that we needed to check over that night, so we were permitted to work on the car in Allan Hamilton’s Porsche Cars Australia workshops, which was then just around the corner from Sandown and anyway, that’s where it was intended to be secured overnight. A full end to end spanner check and a few niggling issues were attended to, ready for the Sunday demonstrations.

There was very little doubt for us that Fangio was annoyed with our involvement in his meeting. He had rightfully expected that he would be the main attraction, him and his car. As it was only demonstration runs, not racing, he was allowed to wear his battered brown helmet. Jack admitted that early in the meeting, with the misfire until the battery change on Sunday morning, he was having trouble keeping up with the Mercedes, even just keeping it in sight. However, by the final run on Sunday, the BT19 was giving as good as it had ever had and he could easily hold onto it. Jack was pleased with the opportunity to display his championship winning car here in Australia. It appeared every time, on schedule and always returned to the pits to the applause of the many spectators. Remember: this was at a far distant time, a long time before we had an annual F1 race and many years after the Tasman series had ended.

After the Fangio meeting a proper enclosed trailer was acquired, and is still used to this day. The car returned to Richmond to have further work done. This involved the engine being installed and tested on the Heenan & Froude GB4 dynamometer that had originally been used in 1965 development and Phil Irving, the main RB620 engine designer was invited to attend while the engine was being tested. An excellent photo opportunity was not wasted, with Phil happily standing alongside his engine in the test cell, but only while the engine was stationary.

Forty years further on and that Repco Brabham BT19 is still attending major motorsport events, at most historic meetings and certainly always attends the AGP F1 meeting at Albert Park. Now an extremely important part of the Brabham collection memorabilia, it is in the ongoing care of Nigel Tait who had further developed an already excellent relationship with Jack, especially in his final years. Nigel was the driving force behind getting this project completed in the short time available and for the ultimate benefit of the Repco Company name.

The BT19 is now over 50 years old and may it live forever. It must never be raced again, regardless of who owns it well off into the future! Many years ago it was used in the TV show, Neighbours, when Kylie was cast as a mechanic(?) Regretfully the car was slightly damaged while filming a scene at Calder.

That 620 engine block is one of the engines that was used in 1966, but there were always several engines rotated through the team cars. The chassis however is definitely the only BT19 that Jack drove that year to win his third championship. Sir Jack Brabham has long gone on to drive the race tracks up in Heaven, now, but his outstanding achievements will and should be remembered for a very long time.

Over the following years Don continued to provide newly made parts for all the RB engines, as most of the casting patterns were in his care. He also continued to build other types of race engines, including the Chevy engines for the Alfredo Costanzo F5000 successes and also some Holden Commodore engines for several Bathurst races.

At the time of the Repco Company being dismantled, by an accountant in 1986, I branched out, in partnership, to set up an engineering business, specializing in small volume pistons and quality piston rings. But that, I’m afraid, is a whole different story. Therefore, I’m pleased to announce that I have had the honour of making replacement Repco Brabham pistons, for the engines that continue to have a racing life, including engines used in hillclimb cars and also racing speed boats. That has occasionally involved engines being de-stroked to suit a particular capacity class, but also some were loaded up with longer stroke cranks and the largest sleeves that can be squeezed into the later blocks, giving good reliable grunt in a lightweight package. Interesting times? That they were.

**********

Sadly, Don Halpin passed away in October 2018.

He was never at all fazed by the fame of the many people he met throughout his long career. His advice and problem solving was frequently sought and requested, with his skill at tuning a variety of engines, regardless of the fuel or injection/ carburation installed. He was a very important member of the Repco part of the Repco Brabham years, then when it later changed to the Repco Engine Development Company (REDC), Don was involved with development of the Holden 308 into a F5000 engine and its milder cousin, the L34, for General Motors Holden to produce and install in the (race) Torana. He also developed a smaller L34 engine, based on the Holden 253, for a production speed boat class. For a time he drove a 308 powered HQ Holden, with the 4 speed ‘box option, as his street car. What he modified and learned from the months of L34 development work was incorporated into the modifications he performed/ installed/ tested on his own car. It may well have been quite close to an F5000 engine?

During his Repco years, Don travelled to Indianapolis in 1969 where the Repco Brabham team qualified both cars for the 500. Jack’s car failed to finish, however the Peter Revson car finished 5th. Many teams (in Gasoline Alley) were amazed that they qualified both cars, at a time when teams struggled to qualify even one car. The fuel used at Indy was an alcohol fuel, so the Repco engines were running a slightly higher compression ratio than their petrol engines in Formula 1. His knowledge of the many Repco Brabham engines was sought by many from all over the world, with his ability to supply the correct parts to keep the many engines still in use today.

Don had a good relationship with many prominent race drivers: Kevin Bartlett, Jack Brabham, Peter Brock, Alf Costanzo, Warren Cullen, Alan Hamilton, Johnny Walker, Bob Jane, Frank Matich, Alan Moffat and Alan Jones, to name just a few of them. Many of their championships were won due to Don’s involvement with their teams and the mechanics who maintained the cars.

Australian motorsport has lost another legend. I have lost another friend.

– Bill Freame

(Ed: I recall as a younger man Bill telling me a little more of this story. After working enormous hours to get the car ready, it came together and was ready to fire up late one night. Now, the Repco complex in Richmond comprised a couple of buildings three or four stories high (as I recall), with a narrow laneway in between. Bill told me they towed the Brabham up and down this laneway then roll-started it. Late night, no mufflers, high compression F1 motor, sitting in a brick canyon…the noise was fantastic, but apparently lots of window lights came on! Like all brave motoring enthusiasts, they shut it down, rolled it back into the workshop, pulled down the door and knew nothing about it. 😊)